What is Purchase Order Management? [2024]

Learn how purchase order management keeps your business organized, saves money, and builds stronger supplier ties.

Learn how purchase order management keeps your business organized, saves money, and builds stronger supplier ties.

Imagine this: your business is running smoothly, orders are coming in, and everything seems on track—until an unexpected hiccup in procurement throws a wrench into your operations. Perhaps a critical order was delayed, or worse, the wrong items were delivered, leaving your team scrambling to fix the issue. What if there was a way to prevent such disruptions?

At the heart of every efficient procurement system lies purchase order management. Whether you’re running a small business or a multinational enterprise, mastering this process can be the key to unlocking smoother operations and higher profitability. But what exactly is purchase order management, and why should you even care?

Purchase order management is at the heart of an efficient procurement process. It governs how purchase orders (POs)—the formal documents sent by a buyer to a supplier—are created, approved, tracked, and reconciled. But the real question is, is it just a formality, or does it carry a deeper significance in modern business? To answer that, let us first dive into its essence and its role in ensuring seamless operations.

Without proper purchase order management, chaos lurks at every corner. Imagine missing deadlines, overstocking warehouses, or even worse—understocked ones leading to unsatisfied customers. The core role of PO management is to ensure that businesses procure the right goods at the right time at the right price, avoiding unnecessary costs and waste.

But when we dig a little deeper, it’s more than that. It’s also about building trust, as vendors respect companies that approach purchasing with a degree of professionalism. A properly managed PO system helps maintain transparency and accountability. The cost of neglecting it creates a ripple effect, as it affects operations as whole, including inventory management and order fulfillment.

What makes a purchase order more than just a piece of paper? Its structure. Here are some important components of a PO document:

Buyer and Supplier Details: Contact names, addresses, and relevant identifiers.

Itemized List of Goods or Services: Descriptions, quantities, and unit prices.

Payment Terms: When and how the supplier gets paid.

Delivery Details: Shipping method, date, and location.

Unique PO Number: For tracking and referencing.

Like a symphony, PO management thrives on structure. Here’s a step-by-step breakdown:

Each stage, if done manually, can be arduous and full of errors. However, digital tools ease these burdens, ensuring smoother transitions and fewer mistakes.

So, what are the challenges that one may face with PO management?

Addressing these challenges means adopting systems that prevent, detect, and correct errors before they wreak havoc on a business environment.

Digital purchase order management systems are game-changers in the business world. They reduce manual labor, automate processes, and integrate with other critical systems like inventory management. Imagine a system that automatically alerts you when stock is low and creates a PO with pre-approved supplier terms. It truly takes the word ‘organization’ to a whole other level.

And here lies a subtle yet powerful truth: While not handling POs directly, platforms like OneCart ensure inventory tracking and order processing work in harmony with your purchasing processes, avoiding operational hiccups.

Inventory and purchase orders are two sides of the same coin. Accurate POs ensure your stock levels are neither too high(wasting storage) nor too low(disrupting sales). A well-managed PO system feeds real-time inventory updates, creating a good cycle of data accuracy.

For example, using a tool like OneCart to keep track of your inventory ensures that POs reflect actual needs rather than outdated assumptions. It’s not just about managing inventory—it’s about mastering it.

![]()

What sets modern PO systems apart? The best ones offer:

Great PO management does not come by accidentally. Here are some practices for success:

Purchase order management is the process of creating, tracking, and managing purchase orders(POs) to ensure the accurate and timely procurement of goods or services. Managing PO involves organizing approvals, maintaining records, and reconciling invoices.

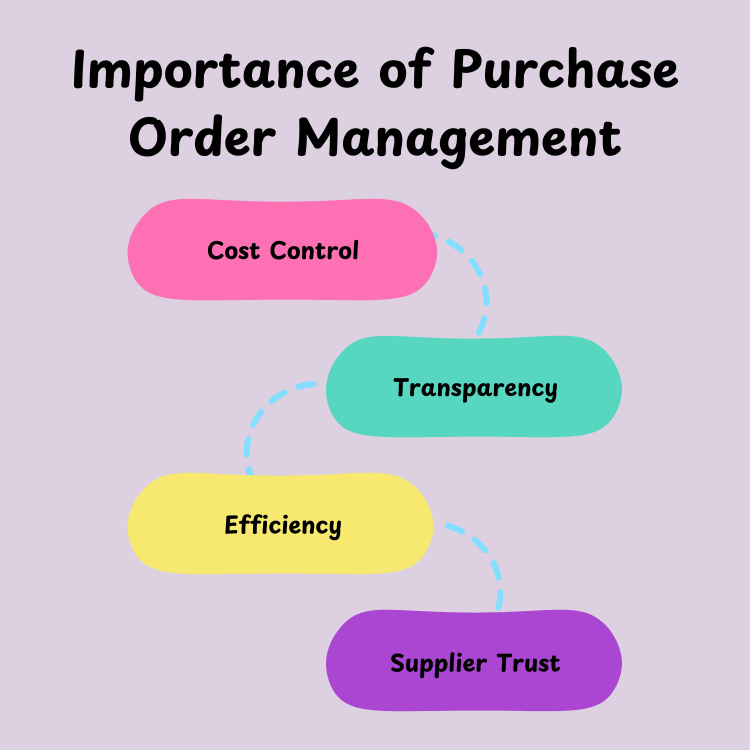

Effective purchase order management helps businesses control costs, maintain transparency, and build stronger supplier relationships.

Common challenges include manual errors, approval delays, lack of visibility into PO status, and duplicate or misplaced orders.

Automation simplifies PO processes by reducing errors, speeding up approvals, providing real-time tracking, and integrating with inventory and order systems.

Purchase orders directly impact inventory levels by ensuring that stock quantities align with business needs. Effective PO management prevents overstocking and understocking, which supports inventory accuracy and order fulfillment.

A reliable PO management system includes customizable workflows, real-time tracking of PO statuses, integration with inventory and financial systems, and detailed reporting to identify trends.

OneCart complements PO management by providing accurate inventory tracking, efficient order processing, and optimal listings management. This ensures that procurement decisions are informed by real-time data.

Purchase order management is more than just a process—it’s the backbone of efficient procurement and operations. As you scale your business, the importance of an effective PO management will definitely be more apparent. It aligns purchasing with business goals, minimizes waste, and builds trust with suppliers.

Have more questions about streamlining your business operations? Discover how OneCart can enhance your inventory tracking and order management today!

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia