What is a Stockout? Everything You Need to Know to Avoid It [2024]

What is a stockout? Learn how to prevent it and keep your inventory in check.

What is a stockout? Learn how to prevent it and keep your inventory in check.

Stockouts have proven to be a major problem for businesses across industries, affecting profitability, customer loyalty, and operational efficiency. But what exactly is a stockout, and how could it affect a business in today’s fast-paced world? Let’s dig a little deeper and discuss the causes, consequences, and actionable ways to prevent it.

A stockout occurs when a product that customers want to purchase is unavailable due to insufficient inventory. This is especially challenging for businesses selling across multiple ecommerce channels. To put into simpler words, it basically means running out of stock at the wrong time, when customers are intending to make that specific item purchase. As a result, it leads to lost sales opportunities and potentially unhappy customers. This dilemma is not a mere inconvenience but a sign that a business needs to improve its inventory management processes.

Imagine walking into a store to buy your favorite chocolate only to find an empty shelf. Or have you had the experience of wanting to order a gadget online, only to be greeted with an “Out of Stock” message? These are everyday examples of stockouts, and while they may seem like a minor inconvenience, they can have a significant impact on both businesses and customers.

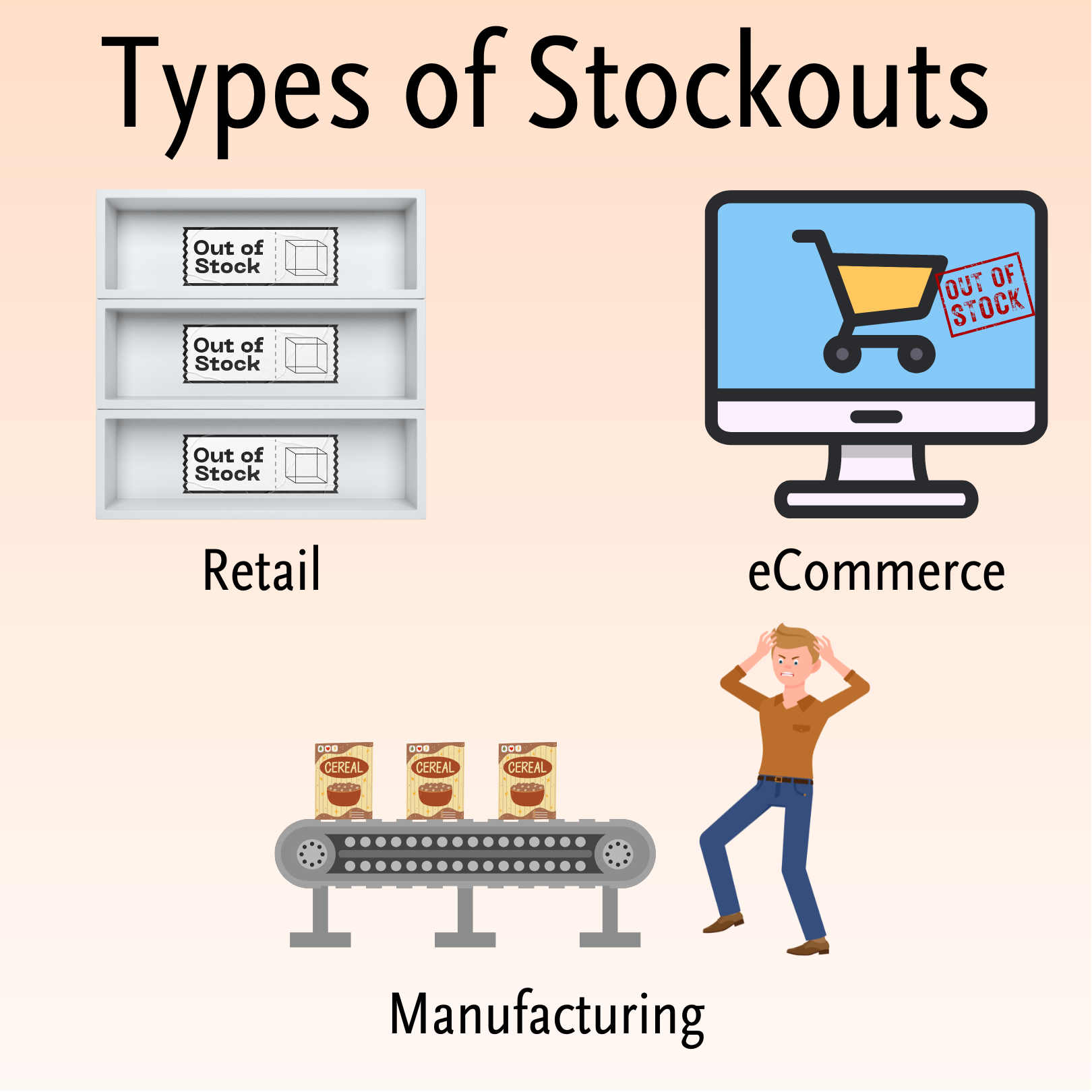

When we look at things from an inventory management perspective, a stockout is the result of failure in planning and forecasting demand. This is quite an indication of poor coordination between supply chains, warehouses, and sales operations. Regardless of the type of business (retail, eCommerce, or manufacturing), stockouts can really disrupt workflows and require businesses to rethink their strategies.

Not all stockouts are created equal. Let’s have a look at how they differ across industries:

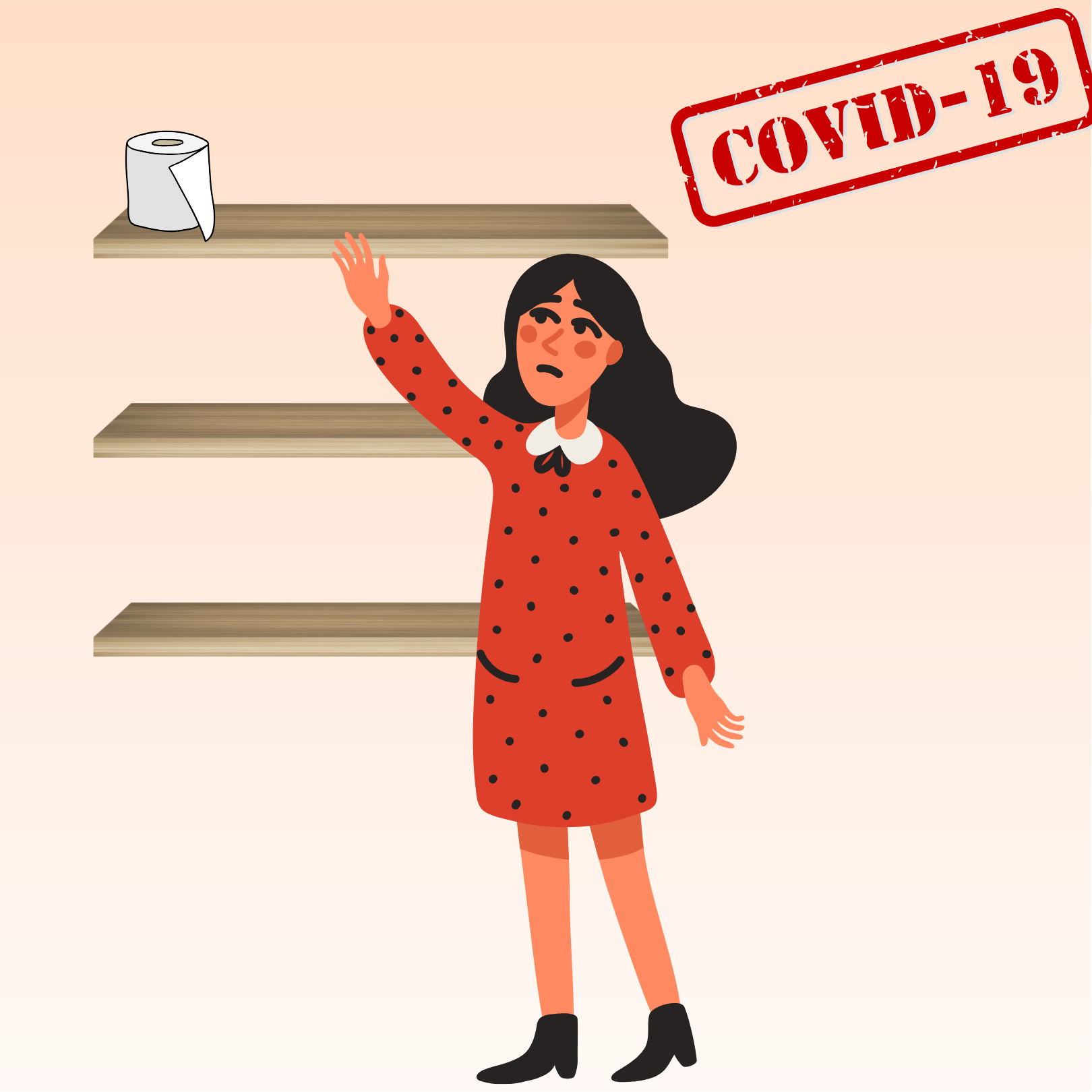

Real-Life Example: During the COVID-19 pandemic, essential items like toilet paper and hand sanitizers were highly on demand. Businesses struggled to keep up with skyrocketing demand, showcasing how unprepared systems can lead to a stockout during crises.

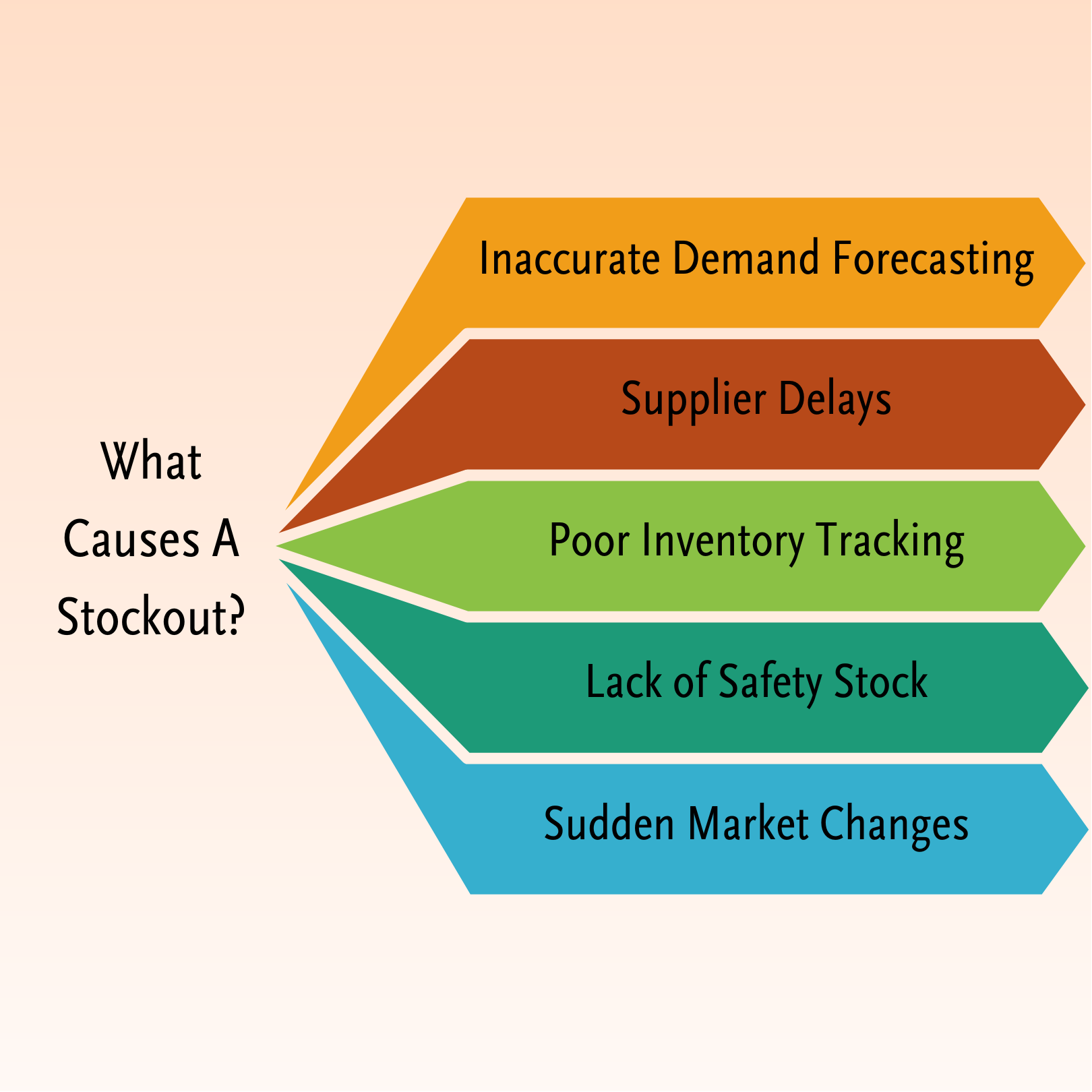

There are a variety of reasons why a stockout may happen, many of which stem from poor planning or unexpected disruptions. Here are the most common causes:

Failing to predict customer needs accurately can lead to overordering or underordering inventory. For example, underestimating demand for a trending product can leave shelves empty, while overestimating leads to unsold goods. Learn more about effective inventory forecasting across multiple channels.

Unfortunately, even if you plan well, delays on your supplier’s end may result in stockouts. Suppliers may face issues like transportation problems or shortage of raw materials that are out of your control.

If you manage your inventory manually, especially for a scaling business, it can be incredibly hard to know when stock levels are running low. Without real-time visibility, it is easy to overlook low stock alerts or miscalculate replenishment needs. This is why having a robust inventory management system is crucial for growing businesses.

Not having any reserve inventory leaves no buffer for unexpected demand spikes. Learn more about avoiding overselling and implementing effective inventory tracking systems.

A viral trend or unexpected global events can create demand spikes, really having a big impact on unprepared supply chains. The earlier example during the COVID-19 pandemic showcases exactly this potential problem.

One may reason that stockouts just cost businesses money, however, that is not actually the big picture. It costs relationships as well. When customers are unable to find a product, they may turn to competitors, disrupting your entire sales funnel. Here’s how:

When customers are unable to find a product, they may turn to competitors, causing immediate sales losses. Over time, frequent stockouts can impact customer loyalty, further impacting long-term profitability.

If you have frequent stockouts, it can damage the overall perception of your brand’s reliability and professionalism. While such issues may not always surface immediately, the long-term impact on your brand’s identity and credibility can be substantial.

The “online” era we live in is both a blessing and a curse because unhappy customers may share their negative experiences online, amplifying the damage to your brand’s reputation. Unlike brand reputation issues, which accumulate over time, customer frustration tends to have an immediate and visible effect.

It can actually cost a business more when running out of stock due to handling of backorders, expedited shipping, and alternative sourcing. A proper order management system is essential for preventing fulfillment delays and maintaining operational efficiency.

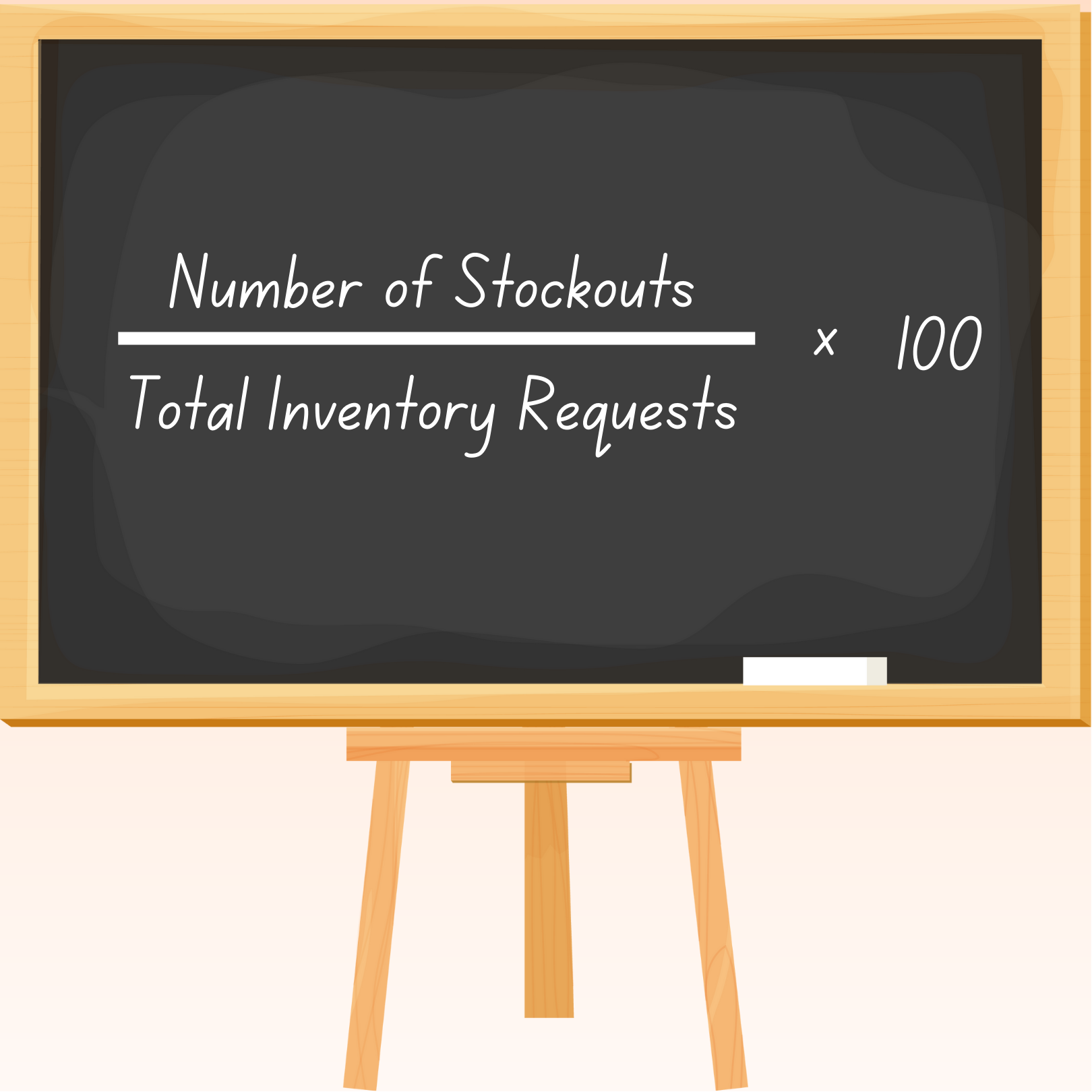

This metric shows how often stockouts occur relative to demand. It’s for evaluating inventory management efficiency.

For example, imagine a retail store receives 1,000 inventory requests for different items in a month. Out of these, 50 requests are not fulfilled due to stockouts. Using the formula:

Stockout Rate = (Number of Stockouts / Total Inventory Requests) x 100 Stockout Rate = (50 / 1,000) x 100 Stockout Rate = 5%

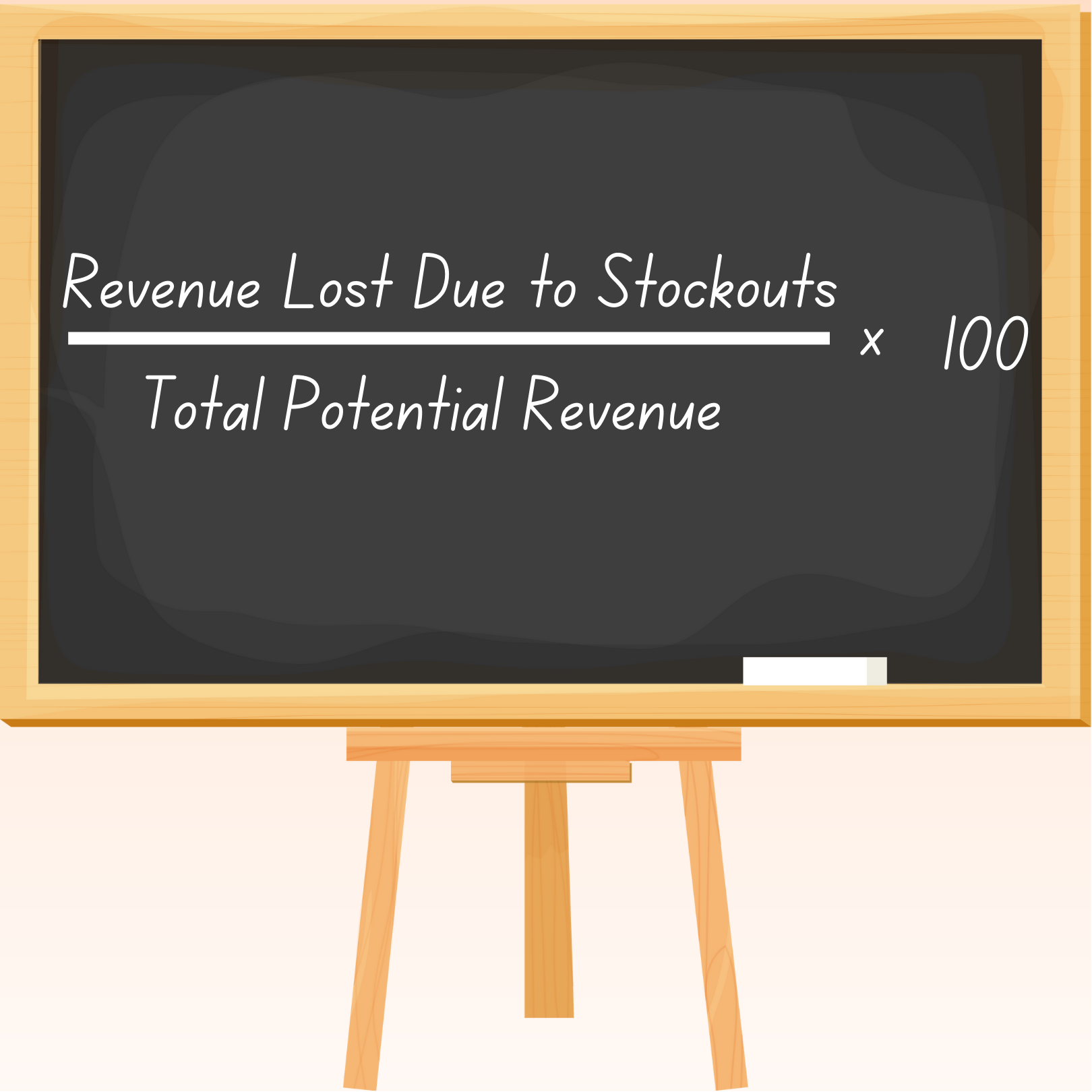

This tracks the revenue lost due to unavailable inventory. It’s a simple indication to illustrate how much revenue a business is missing out on due to unavailability of products.

For example, a retail store had a potential revenue of $100,000 in a month. However, due to stockouts, it lost $10,000 in sales. Using the formula:

Lost Sales Percentage = (Revenue Lost Due to Stockouts / Total Potential Revenue) x 100 Lost Sales Percentage = ($10,000 / $100,000) x 100 Lost Sales Percentage = 10%

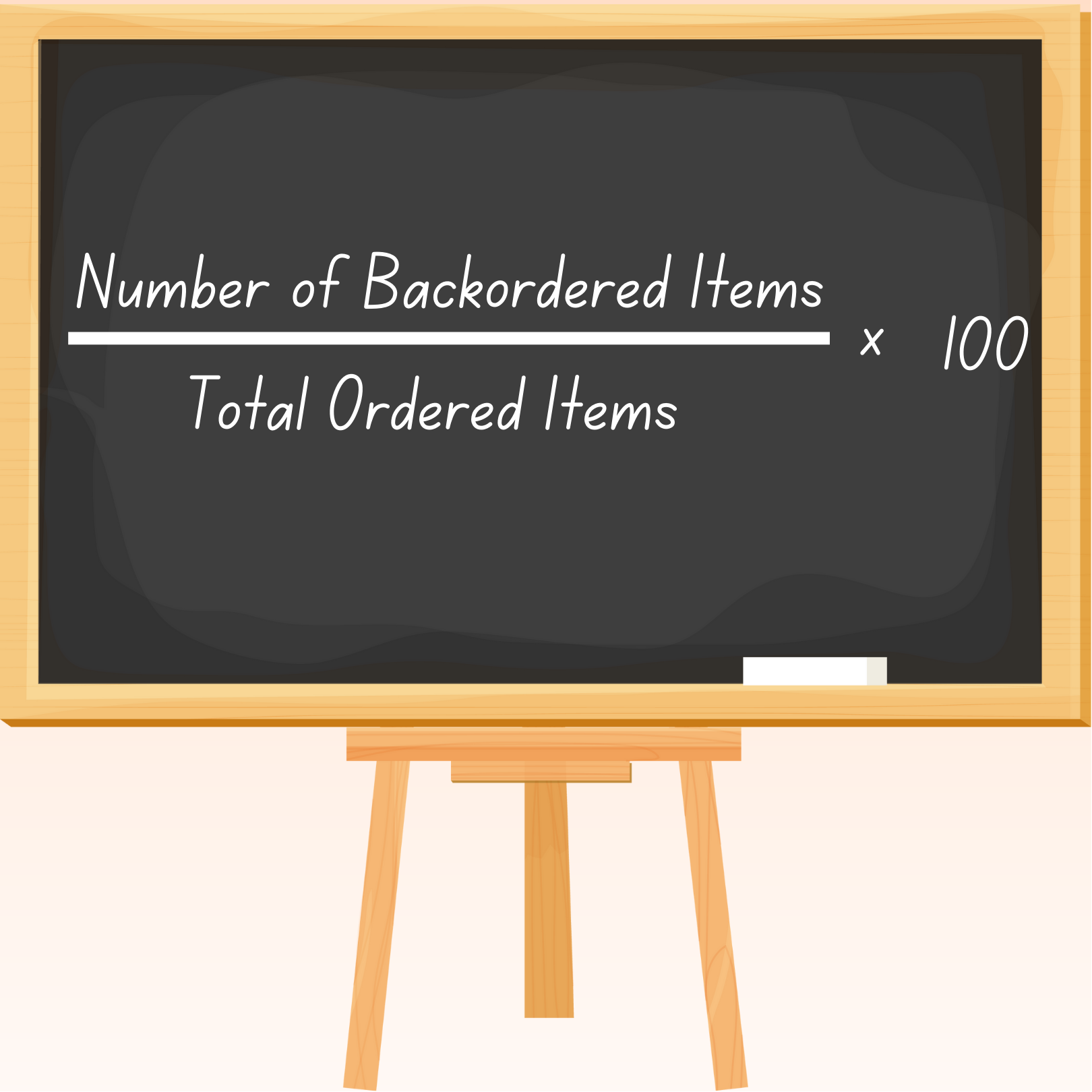

This measures how many orders are delayed because of stockouts. Knowing this highlights how often customers are willing to wait for a product rather than cancel their purchases entirely.

For example, an online retailer received 500 orders in a month. Out of these, 100 were delayed because the items were out of stock and had to be backordered. Using the formula:

Backorder Rate = (Number of Backordered Items / Total Ordered Items) x 100 Backorder Rate = (100 / 500) x 100 Backorder Rate = 20%

Just as a gymnast balances on a beam, stock is all about balance, requiring both competitive pricing and strategic inventory management. While stockouts may cause immediate losses, overstocking results in cash being overinvested on unsold products. Therefore, a system needs to be in place for inventory levels to meet the demand without excess.

Preventing stockouts is not something that happens by coincidence, but requires proactive planning, smart tools, and clear strategies. Here’s how:

Analyze sales trends and customer data to anticipate future demand accurately. One effective way to do this is by using historical data, market trends, and advanced analytics to anticipate changes in demand.

Always keep a buffer of essential inventory to handle any unexpected demand. By doing this, businesses can continue to fulfill orders promptly, even during unforeseen disruptions or circumstances that may cause a surge in demand.

Implement technology like OneCart, which provides real-time stock visibility, automates alerts, and predicts low inventory. Using such a system reduces any possible delays and enables proactive replenishment.

Find appropriate and reliable suppliers to work with to ensure timely delivery and build contingency plans. Open communication, performance monitoring, and agreements on such contingency plans allow businesses to circumvent challenges like delayed shipments or supply shortages.

Consider leveraging systems that integrate with your operations, like OneCart, to streamline processes and minimize unnecessary risks. While real-time inventory management is important, having an overall software solution helps to reduce human errors, save time, and provide actionable insights to prevent stockouts.

When a business effectively prevents stockouts, it leads to:

A stockout occurs when an item is unavailable for sale or production due to insufficient inventory.

Frustrated customers may turn to competitors, affecting loyalty and long-term revenue.

Stockouts can include running out of seasonal products, unavailability of raw materials in manufacturing, or “Out of Stock” messages in eCommerce listings.

Yes, with proactive forecasting, technology like OneCart, and safety stock measures.

Both are harmful, but stockouts show immediate effects since it impacts customer satisfaction and revenue.

Tools like OneCart offer real-time inventory tracking, automated alerts, and advanced analytics to minimize inventory issues.

No matter the size of the business, stockouts are an issue that has to be faced one time or another. However, by understanding the root cause, impact, and solutions like OneCart, businesses can create a stockout-free future. It’s like the saying goes, ‘When you fail to plan, you plan to fail’. Whether you’re managing a small eCommerce store or a large-scale supply chain, avoiding stockouts is crucial for profitability and customer satisfaction.

Ready to eliminate stockouts from your business operations? Start your free trial with Onecart today and discover how our advanced inventory management solutions can help you stay ahead of the curve.

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia