Minimum Quantity Order (MOQ): What It Is, Why It Matters, and How to Optimize It [2024]

Learn how MOQ impacts supply chain efficiency, reduces costs, and drives profitability, and discover strategies to optimize it for your business.

Learn how MOQ impacts supply chain efficiency, reduces costs, and drives profitability, and discover strategies to optimize it for your business.

For someone looking to be successful in the business world, there are so many business jargons to learn and understand. The term Minimum Quantity Order(MOQ) is no exception as it is crucial to maintain profitability, manage inventory, and streamline supply chain operations. Regardless of whether you are a startup handling supplier agreements or an established eCommerce business refining your purchasing strategy, MOQs play an important role in shaping the structure of your operations.

MOQ is an abbreviation for Minimum Order Quantity. It indicates the minimum number of items required for a transaction, especially in the business-to-business(B2B) dealings.

Minimum Quantity Order(MOQ) refers to the smallest number of units a supplier is willing to sell in a single order. The reason for an MOQ is usually so that manufacturers or wholesalers can ensure production and distribution costs are met.

For example, if a manufacturer tells you that the MOQ is 500 units, that simply means that you must order at least 500 units per transaction to engage with the respective supplier.

MOQs exist because suppliers need to cover the cost of production, materials, and logistics. They also:

The key is balance. Businesses use MOQs to balance their production and distribution needs with profitability. Here’s how:

Suppliers need a form of assurance that the effort and costs of production are worthwhile. MOQs help them achieve consistent revenue while managing raw materials effectively.

For example, a T-shirt supplier has fixed costs like setting up a machine and preparing designs. If someone orders, 50 shirts, these costs are spread over too few items, making it expensive and unprofitable. But by setting a Minimum Order Quantity (MOQ) of 500 shirts, the supplier can:

MOQs help suppliers stay efficient and profitable, while buyers get better prices for meeting the minimum.

Without MOQs, suppliers take the risk of producing items that might not actually sell, leading to wasted resources. With the introduction of MOQ, only items with guaranteed demand are manufactured.

MOQ calculations are important to align production costs with profitability. MOQ is calculated by taking into account factors like raw material costs, labor, and overheads. For example:

Thus, MOQ numbers can largely differ depending on the industry that you belong in.

Setting an MOQ allows suppliers to take advantage of economies of scale, reducing per-unit cost of production. Bulk manufacturing minimizes overhead costs per unit, which benefits buyers through lower prices for larger order volumes, ultimately enhancing profitability for both parties.

Businesses are able to have a more optimal inventory level, avoiding shortages or overstock. This helps streamline storage management and minimizes the risk of excess inventory costs or missed sales opportunities due to insufficient stock.

When buyers meet MOQ requirements, they often gain leverage to negotiate better payment terms with suppliers. This can improve cash flow by allowing businesses to better manage liquidity and allocate resources efficiently while still meeting their production needs.

It can actually cost a business more when running out of stock due to handling of backorders, expedited shipping, and alternative sourcing. MOQs mitigate these risks by ensuring consistent supply and reducing the operational costs associated with disruptions.

As mentioned previously, MOQs bring about benefits for both suppliers and buyers. However, they can pose challenges for buyers as well. Here are some:

Small businesses may struggle to meet a high MOQ that has been set due to limited capital or storage space. If they do go on to meet these high MOQs, it could lead to overcommitment and potential inventory issues.

For instance, a survey revealed that 42% of small and medium-sized businesses (SMBs) struggle with “their inability to meet minimum order sizes set by vendors,” hindering their ability to compete with larger companies.

For big corporations that have been firmly established, large order investments may not be that much of a risk. However, for businesses with fluctuating demand, orders with a significant upfront investment could prove to be extremely risky.

A high MOQ requirement is not the end of the world for a business. Sometimes, you will be able to negotiate a lower MOQ with some strategies in place.

“You can’t always get what you want. But if you try sometimes, you just might find you get what you need” - The Rolling Stones

If you already have a supplier at the moment, continue to establish trust by demonstrating reliability through consistent business and clear communication. Over time, this trust incentivizes suppliers to become more flexible with their MOQ requirements, especially for loyal clients.

Commit to regular orders over time. Once such a business relationship is established, suppliers are more likely to lower the MOQ for buyers offering predictable revenue.

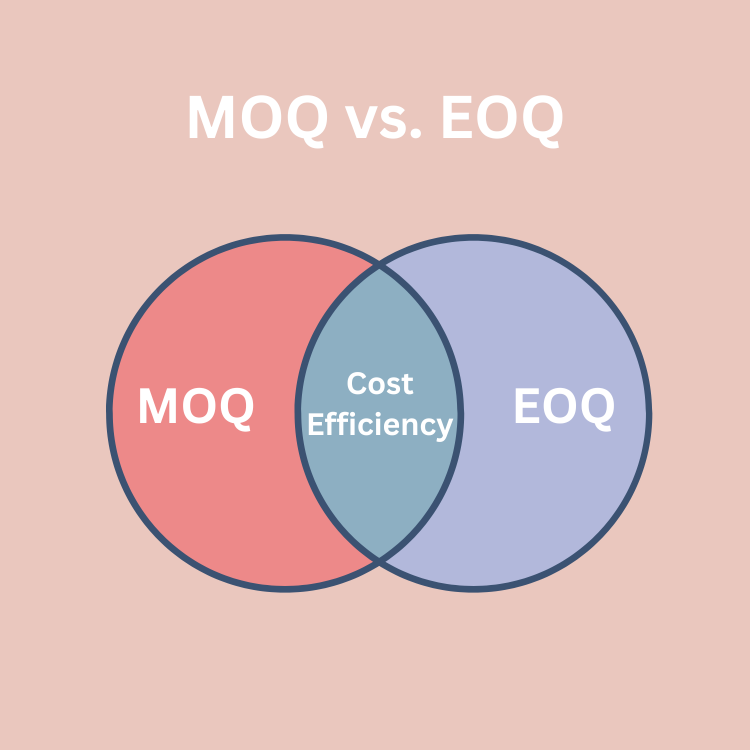

EOQ, or Economic Order Quantity, refers to the optimal number of units a business should order to minimize costs related to purchasing and storage. It balances the trade-offs between order frequency and storage costs, ensuring efficient inventory management.

While MOQ is supplier-driven as it is the minimum requirement to ensure production viability, EOQ is buyer-driven since it is a metric aimed at cost-efficiency on the buyers’ side. Businesses need to balance both to achieve profitability.

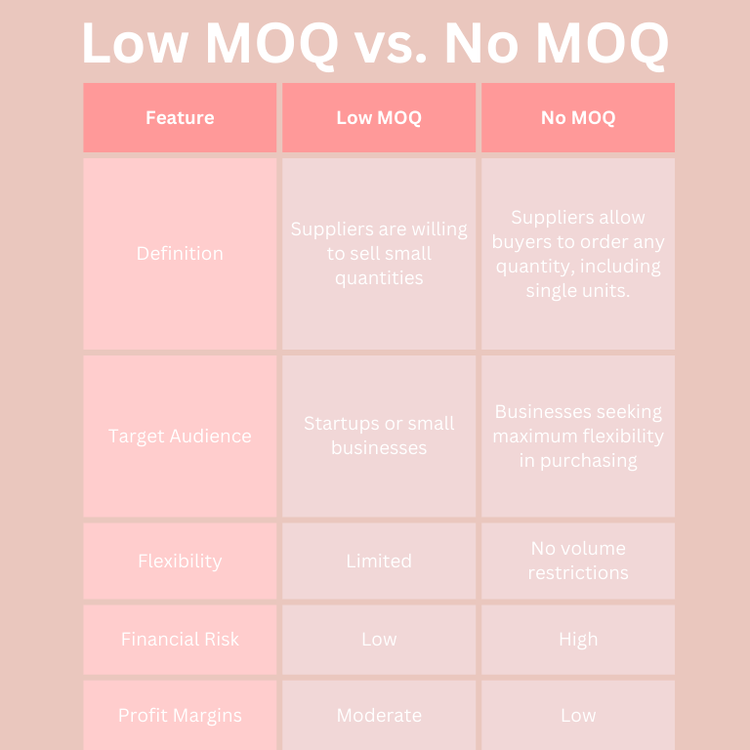

Low MOQ is when suppliers are willing to sell small quantities, which in turn, caters to startups or small businesses. This allows businesses to test products and manage smaller inventories without significant financial risk.

No MOQ provides businesses with maximum flexibility, allowing them to order exactly what they need without volume restrictions. However, this benefit is attached along with added expense of higher per-unit costs, which can reduce profit margins significantly. Though no MOQ offers convenience, businesses must weigh the trade-off between flexibility and cost-efficiency.

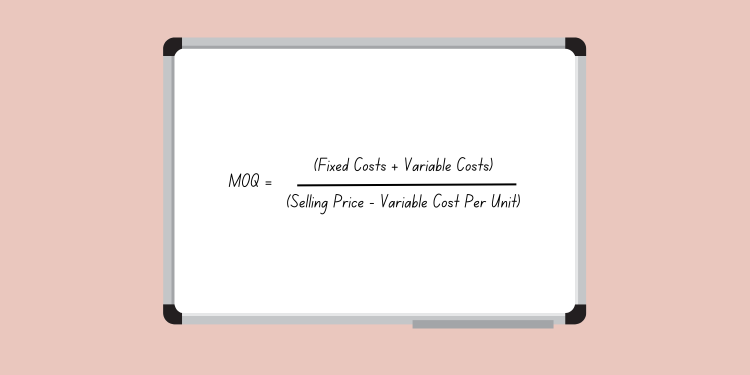

MOQ = (Fixed Costs + Variable Costs) / (Selling Price - Variable Cost Per Unit)

Example:

Calculation: MOQ = ($2,000 + $500) / ($50 - $20) MOQ = $2,500 / $30 MOQ = 83.33 units

To recover all your costs and ensure profitability, you need to sell at least 84 units.

In eCommerce, MOQ mostly appears in B2B transactions. For examples, wholesalers may require retailers to purchase 500 units of a product. This ensures that they meet the production costs while offering competitive prices to retailers.

Dropshipping platforms typically have low or no MOQ requirements, making them attractive to small businesses and startups. However, for sellers on platforms like Amazon, MOQs may be enforced to prevent fulfillment inefficiencies. Platforms like OneCart streamline inventory and order management, enabling businesses to meet MOQ requirements efficiently.

One may think that high MOQ requirements pose a dead-end situation for smaller businesses. Here are two ways to possibly create a workaround solution:

Search out collaborations with other businesses to collectively meet MOQs and share costs. By pooling resources and placing joint orders, businesses can collectively meet the supplier’s minimum order quantity while sharing costs. This approach reduces financial strain and fosters partnerships within the industry.

In the era we live in today, there is always a competitor out there, even for suppliers. Local suppliers often provide more flexible MOQ terms compared to larger, global manufacturers. By sourcing locally, businesses can benefit from lower transportation costs, faster delivery times, and reduced logistical complications. Another point to add is that local suppliers may be more open to negotiation, making it easier for smaller businesses to obtain a more favorable agreement in business transactions.

Digital platforms like OneCart are revolutionizing MOQ management by offering tools that enhance efficiency and decision-making. They enable businesses to track inventory, automate reorders, and optimize supplier relationships.

As sustainability becomes a priority, businesses are rethinking MOQ strategies to minimize environmental impact. By revising MOQs to align with eco-conscious goals, companies can reduce waste from overproduction and excessive inventory.

MOQ stands for Minimum Order Quantity, a supplier’s minimum purchase requirement.

Use cost-based formulas factoring in production and selling price. MOQ = (Fixed Costs + Variable Costs) / (Selling Price - Variable Cost Per Unit)

Low MOQ refers to smaller minimum order requirements, ideal for startups and small businesses.

No MOQ allows buyers to order without volume restrictions but often at a higher cost.

MOQs are an underrated concept that serve as a strong foundation for an efficient supply chain and inventory management, influencing profitability, waste reduction, and operational efficiency. While high MOQs can pose challenges, especially for smaller businesses, strategies like pooling resources, leveraging local suppliers, and negotiating terms can provide practical solutions. Each business needs to assess their needs and leverage solutions like OneCart to navigate MOQ requirements effectively.

Ready to optimize your eCommerce business and streamline supplier relationships? Start your free trial with Onecart today and discover how our advanced inventory management solutions can empower you with cutting-edge tools to reach optimized results!

Automate & Scale Your Online Business with OneCart

Start a Free TrialUsed by hundreds of merchants in Singapore & Southeast Asia